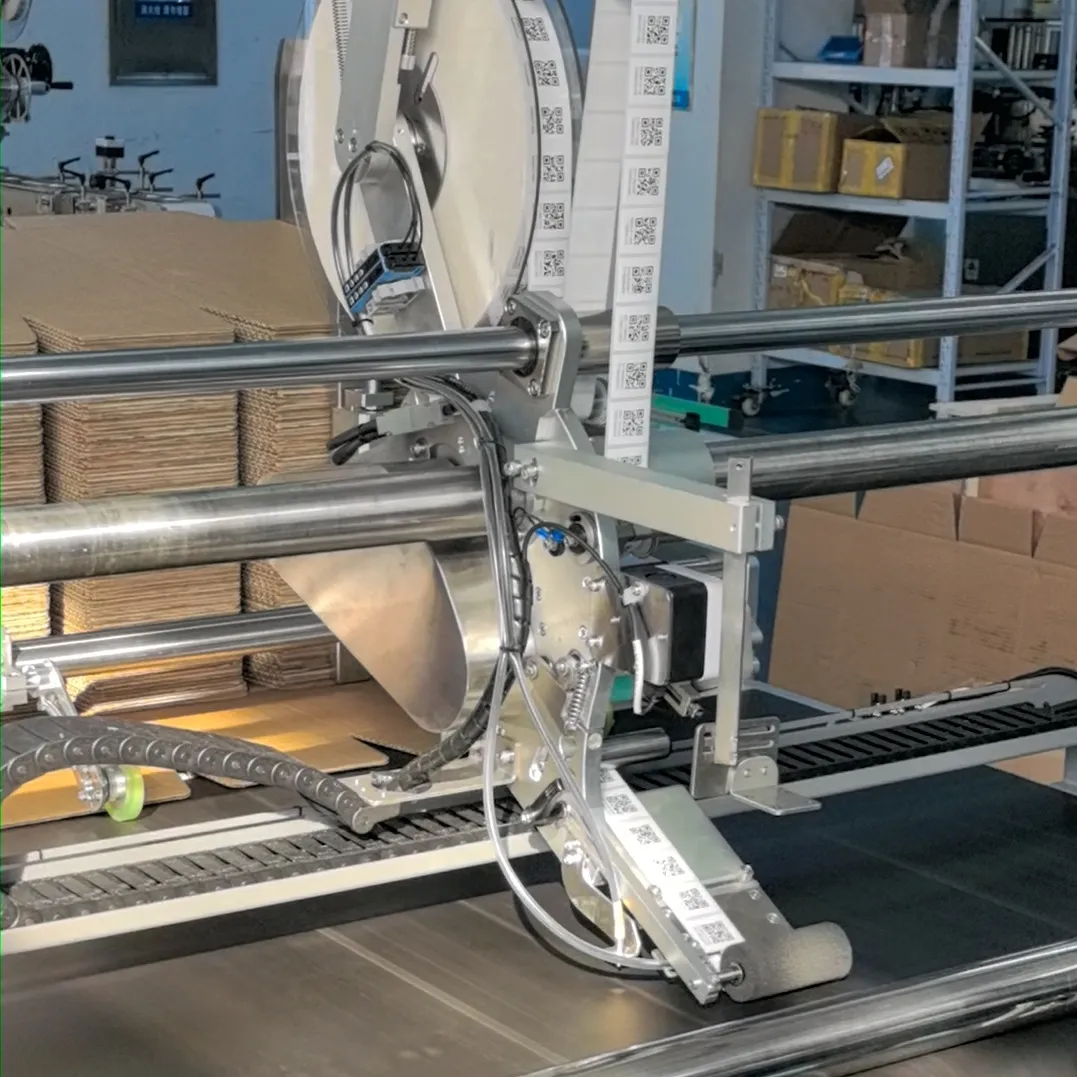

In recent years, an increasing number of businesses have opted for automated equipment to label large cartons. The traditional method involved manual labeling, which resulted in inconsistent label placement, high costs, and low efficiency. This not only caused the labels on the boxes to be uneven, affecting their appearance, but also wasted labor and resources. The automatic paging and labeling machine launched today effectively addresses these issues.

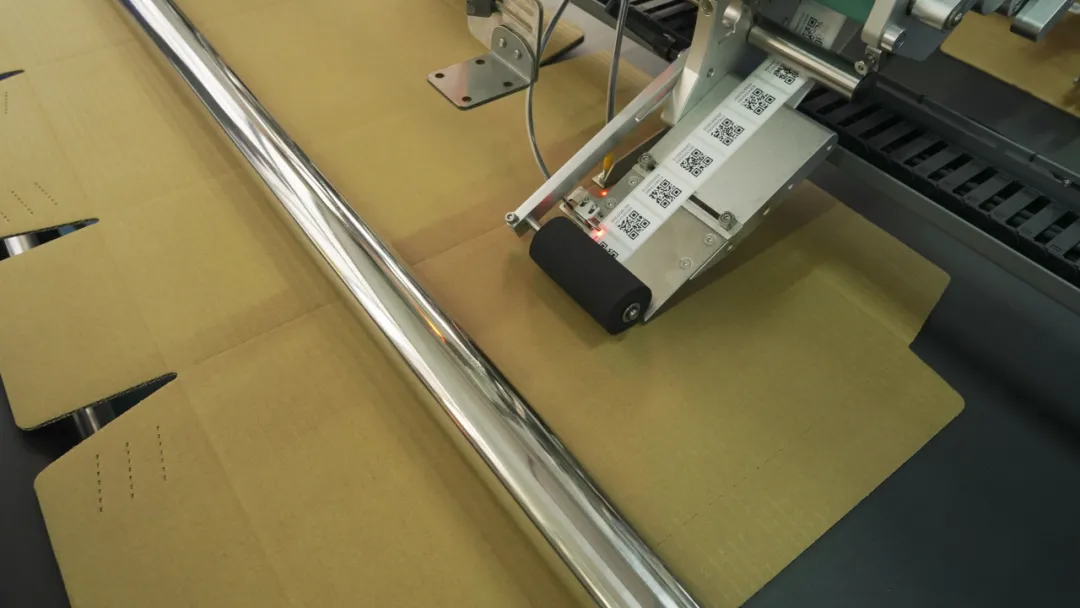

Santuo’s stacked cartons separating and labeling system first uses a separating machine to evenly separate the stacked cartons and then applies labels. This significantly reduces the workload of manual operations. The equipment can be optionally equipped with a visual inspection system to remove products with poor print quality, unsuccessful barcode and QR code recognition, and missed labels.

Application:

Sheets separating and labeling for unformed large cartons.

Fuctional Features

1. Servo-Driven Labeling Head:The labeling head is designed for automatic horizontal movement. The use of a servo drive allows for quick and precise adjustments of the labeling head position, enhancing efficiency during production changes.

2. Flexible Labeling Options: The machine offers flexibility in labeling, allowing for both top and bottom labeling or single-sided labeling as needed.

3. Efficient Paper Handling: Automatic paper collection and stacking ensure that the process is streamlined and that the output is neatly organized.

4. Optional Features: The machine can be customized with additional features such as visual inspection and rejection, which can be beneficial for quality control.

5. Versatile Compatibility: The equipment has a broad compatibility range, accommodating paper lengths from 300 to 1200 mm and widths from 380 to 800 mm.

Technical Parameters

|

Capacity |

40 to 60 sheets/min |

|

Feeder Speed |

50 meters/min |

|

Main Conveyor Belt Speed |

50 meters/min |

|

Operating Air Pressure |

≥ 0.6 Mpa |

|

Power Supply |

220 VAC, 50 Hz |