With the continuous development of the economy, consumers are increasingly demanding higher quality standards for pharmaceutical and daily chemical products. How to effectively conduct product quality inspections and how to enhance the aesthetic appeal of product packaging and the accuracy of information dissemination have become key concerns for many manufacturers.

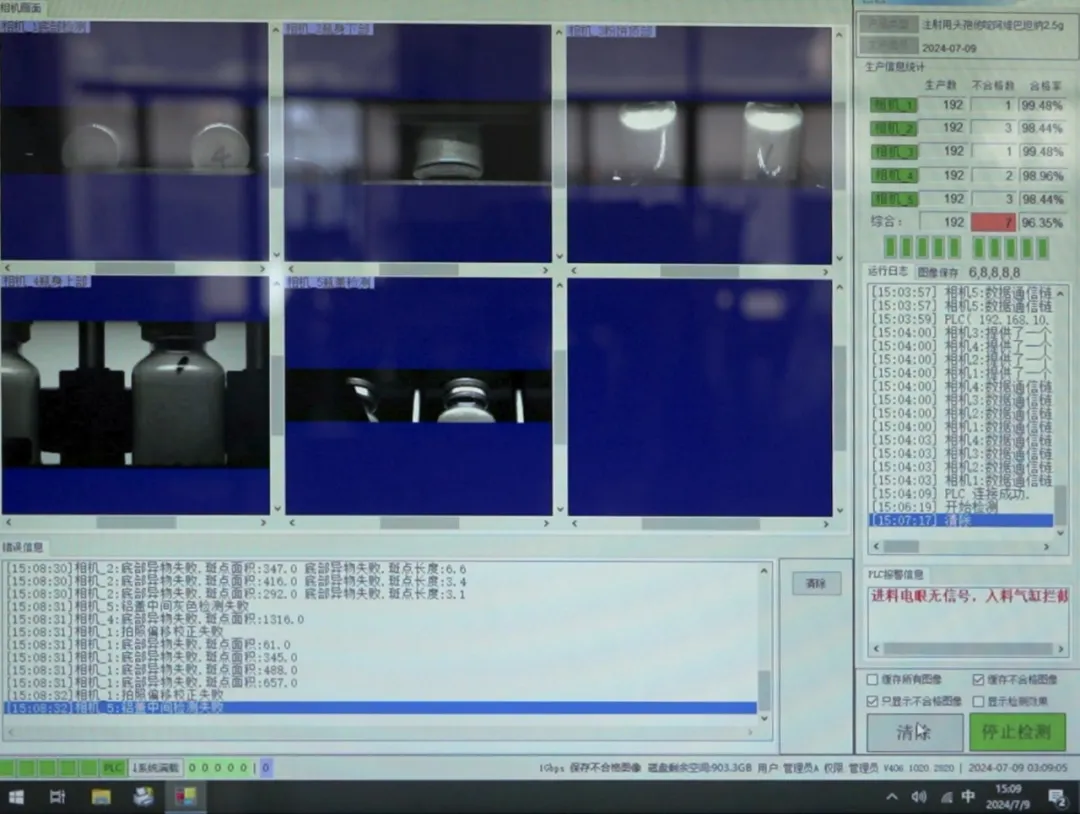

Santuo’s integrated powder vial inspection and labeling machine combines the functions of light inspection and labeling. Through image processing systems and algorithmic software, it identifies defects in the cap, body, bottom, or contents of vials, thereby improving accuracy, reducing misjudgment and miss rates, and accurately distinguishing between defective and qualified products.

While performing visual inspection, the equipment also features automatic printing and re-labeling capabilities, enhancing production efficiency, and meeting the high standards of modern production. It is the ideal choice for improving product quality and production efficiency.

Functional Features

Dual Inverted Bottle Detection

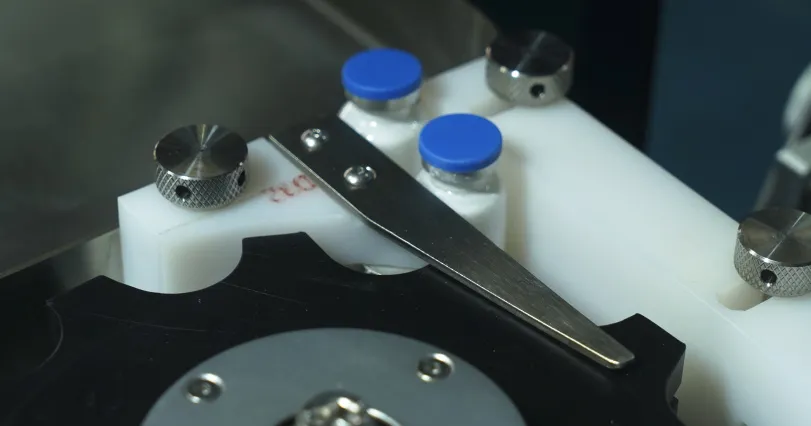

The feeding conveyor belt employs a mechanical structure for automatic rejection of inverted bottles, with photoelectric detection control to intercept and ensure safe equipment operation.

Improved Detection Accuracy

The seamless integration of the bottle separation and vertical rollers, with the camera assisted by a rotary bottle mechanism, ensures 360-degree photography for no missed inspections. The image processing system and algorithmic software process and identify defects in the vial cap, body, bottom, and contents, accurately distinguishing between defective and qualified products to improve accuracy.

Enhanced Production Efficiency

The integrated design of light inspection and labeling functions in a single structure saves space and reduces the need for manual operation.

Precise Rejection

Utilizing the Bernoulli principle, the star wheel suction rejection mechanism ensures precise and efficient rejection, with simple collection and processing.

Compliance with GMP Standards

The main body of the equipment is made of high-quality stainless steel and aluminum alloy, with special parts using high molecular materials to prevent rust and contamination.

Technical Specifications

|

Labeling Speed |

600 bottle/min (varies with the object to be labeled and the length of the label) |

|

Labeling Accuracy |

±0.5mm (excluding errors from the object and label themselves) |

|

Power Supply and Power Consumption |

220VAC, 50/60Hz, 3350W |

|

Operating Air Pressure |

≥0.6MPA |

|

Overall Speed |

500 bottles per minute |

|

Dimensions (L×W×H) |

4700×1500×2350mm |